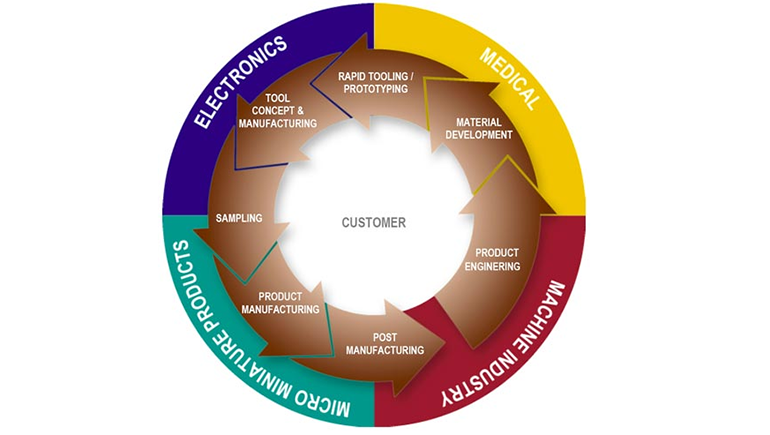

One Stop Solution Provider

SPT in-house processes

- Material preparation

- Toolmaking

- Injection molding

- Thermal processes

- Post-processing

Die gesamte Entwicklungskette: vom Keramikpulver bis hin zur Massenproduktion im CIM-Verfahren

SPT is the first address for custom made ultra precision ceramic parts. During the entire engineering and development process our specialized staff works together with the customer to optimize the target product and production chain.

bild

Product Engineering

Our dedicated technical staff communicates with the customers to match their needs with the requirements of the CIM process.

bild

Material Development

If one of our standard materials does not fit the customer’s needs, our talented material scientists can develop custom material solutions.

bild

Rapid Tooling / Prototyping

Time to market is essential. Several options for producing quick-turn prototypes are available.

bild

Tool Concept & Manufacturing

Utilizing the latest CAD/CAM techniques, molds are designed and manufactured to very demanding specifications.

bild

Sampling

After tooling is complete, first samples are produced. Tool or process adjustments are determined.

bild

Product Manufacturing

We are highly capable of producing runs from hundreds of parts up to several million. With our global presence, production can be handled close to the customer.

bild

Post Manufacturing

Well determined dimensions may require further processing after sintering - CNC machining provides required results.