Ceramic Injection Molding Process

The CIM-Process - Ceramic Injection Molding

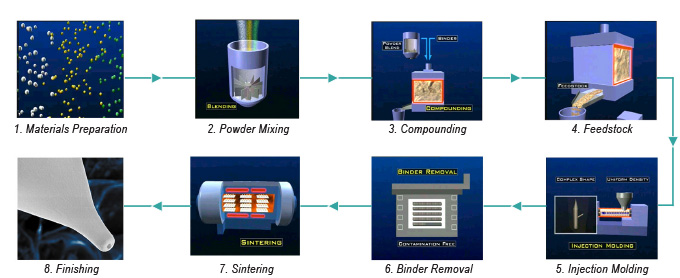

The CIM process combines solids through Injection Molding and sintering techniques. In this way, very hard materials can be used to produce complex shapes that would be too difficult, too expensive or impossible to produce using conventional methods. The Ceramic Injection Molding process can also be used to connect components that previously had to be assembled.

1. Injection Molding ToolThe Injection Molding Tool is designed and built in-house with CAD/CAM technology. This means that the Ceramic Part can be manufactured exactly according to the CAD drawings. |

2. Raw Material PreparationThe Ceramic Powder is selected based on the customer's requirements and taking into account the grain size, shape and distribution. Under carefully monitored conditions, the various types of powder are mixed with special binders and additives to obtain a mixture that is ready for injection molding. The properties of the resulting raw material are recorded precisely by SPT as part of quality control and for batch tracing. |

3. Injection MoldingPurpose-built Injection Molding Machines are used to fill the raw material into the molds, which are similar to the molds for the Plastic Injection Molding process. The machine configuration requires very tight tolerances and wear-resistant components that must be able to withstand the abrasive powders. The fully automatic molding process guarantees uniform consistency and ensures the automation of statistical process data collection (Statistical Process Control/SPC). |

4. In Process ControlSPT has developed innovative monitoring techniques that make it possible to monitor the internal Properties of opaque Materials. This monitoring during the molding process provides data in real time, which can reduce costs and increase quality. |

5. Thermal Post-TreatmentBinder Removal: Next, the binder is removed from the so-called preform through evaporation and an exothermic reaction, leaving only a fraction of the binder behind. The way solvents are disposed of during the binder removal stage demonstrates SPT's commitment to environmental protection. Sintering: Depending on the material, the parts are sintered in an oxidizing or reducing atmosphere or in a vacuum. Subsequent Compression (HIP): For certain applications, the Injection Molded parts can be treated again using hot isostatic pressing (HIP) in order to increase their density and strength. |

6. Post-ProcessingVarious processing methods are available for applications that require a certain Surface Quality or Precision that exceed the quality achieved through sintering. Thanks to the possibility to fall back on our highly qualified employees in Singapore, China and the Philippines, SPT is able to adhere to exceptional tolerances and to deliver goods at economical prices. |

7. Final InspectionSPT works closely with the customer to define control and evaluation criteria as early as during the design phase. State-of-the-art measuring technology is used to ensure that the manufactured parts comply with the technical specifications. |

The Technical Guide to Ceramic Injection Molding Process

Ceramic injection molding is a manufacturing process used to produce complex ceramic parts with high precision and accuracy. This guide provides an overview of the process, including the materials used, equipment required, and the steps involved in producing ceramic parts through injection molding. Whether you're a novice or an experienced professional, this guide will help you understand the basics of ceramic injection molding.

Introduction to Ceramic Injection Molding.

Ceramic injection molding is a manufacturing process that involves injecting a ceramic material into a mold to produce complex parts with high precision and accuracy. This process is commonly used in industries such as aerospace, medical, and electronics, where the production of small, intricate parts is required. In this guide, we will provide an overview of the ceramic injection molding process, including the materials used, equipment required, and the steps involved in producing ceramic parts through injection molding.

Materials Used in Ceramic Injection Molding.

The materials used in ceramic injection molding are typically ceramic powders mixed with a binder material. The binder material is used to hold the ceramic powder together and give it the necessary strength to be molded. Common binder materials include wax, thermoplastic polymers, and thermosetting polymers. The choice of binder material depends on the specific requirements of the part being produced, such as the desired strength, flexibility, and temperature resistance. Once the ceramic part has been molded, the binder material is removed through a process called debinding, leaving behind a pure ceramic part.

Equipment and Machinery Used in Ceramic Injection Molding.

Ceramic injection molding requires specialized equipment and machinery to produce high-quality ceramic parts. The process typically involves a molding machine, which uses a screw or plunger to inject the ceramic material into a mold cavity. The mold is then heated to a high temperature to cure the ceramic material and create a solid part. Other equipment used in the process includes debinding ovens, which remove the binder material from the molded part, and sintering furnaces, which heat the part to a high temperature to achieve its final density and strength. It's important to choose the right equipment and machinery for your specific ceramic injection molding needs to ensure the best possible results.

The Ceramic Injection Molding Process.

The ceramic injection molding process is a highly specialized manufacturing process that involves the use of advanced equipment and machinery. It is used to produce high-quality ceramic parts with complex geometries and tight tolerances. The process involves several steps, including material preparation, injection molding, debinding, and sintering. Each step requires specialized equipment and expertise to ensure the best possible results. If you are considering ceramic injection molding for your manufacturing needs, it's important to work with a trusted supplier who can guide you through the process and help you choose the right equipment and materials for your specific application.

Advantages and Disadvantages of Ceramic Injection Molding.

Like any manufacturing process, ceramic injection molding has its advantages and disadvantages. One of the main advantages is the ability to produce complex geometries with high precision and accuracy. This makes it ideal for applications where tight tolerances are required. Additionally, ceramic parts produced through injection molding are often stronger and more durable than those produced through other methods. However, the process can be expensive and time-consuming, and it may not be suitable for all applications. It's important to carefully consider the pros and cons of ceramic injection molding before deciding if it's the right choice for your manufacturing needs.