About Ceramic Materials

SPT has extensive experience in the field of ceramic materials

Technical ceramics have become a preferred material in many industries today because of their performance, durability and appearance. The properties of most ceramic materials make them suitable for a wide variety of applications.

Upon request, the materials can be certified according to international ISO or ASTM standards.

What are the ceramic materials?

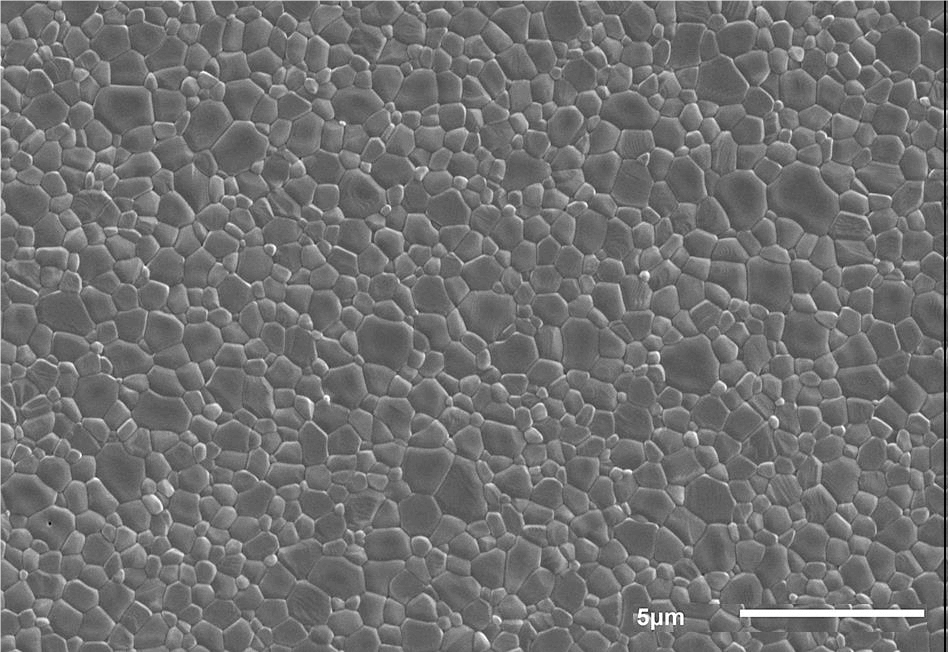

Alumina and zirconia are the most common ceramic materials. Alumina is a white, translucent material that is available in different purity levels. The highest purity level is 99.99% pure. Zirconia is a white, opaque material that is also available in different purity levels.

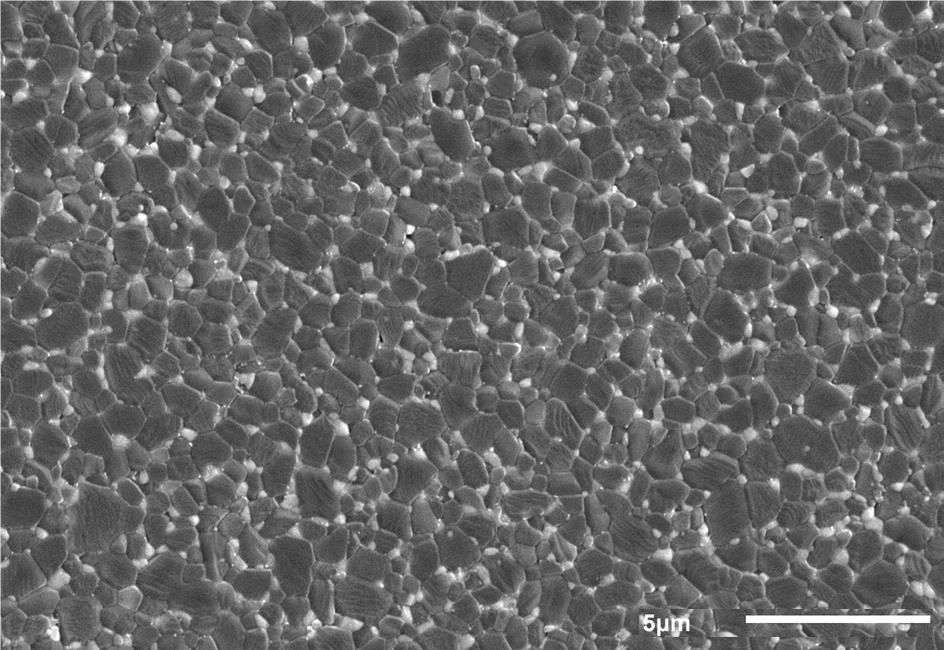

1. Alumina

| Properties | Units | Al2O3 99,7% | Alumina Ceramic Oxide 99,99% | Polycristalline Ruby | Zirconia Toughened Alumina | Zirconia Toughened Alumina | Zirconia Toughened Ruby |

| SPT Denomination | A | C | R | CT | AZ | AZR | |

| Density | g/cm3 | 3.9 | 3.98 | 3.9 | 4.0 | 4.25 | 4.25 |

| Colour | Ivory | White (translucent available) | Red (translucent available) | White | White | Pink | |

| Flexural Strength | MPa | 310 | 710 | 710 | 750 | 930 | 930 |

| Hardness | HV 1 | 1'800 | 2'180 | 2'200 | 2'150 | 2'060 | 2'100 |

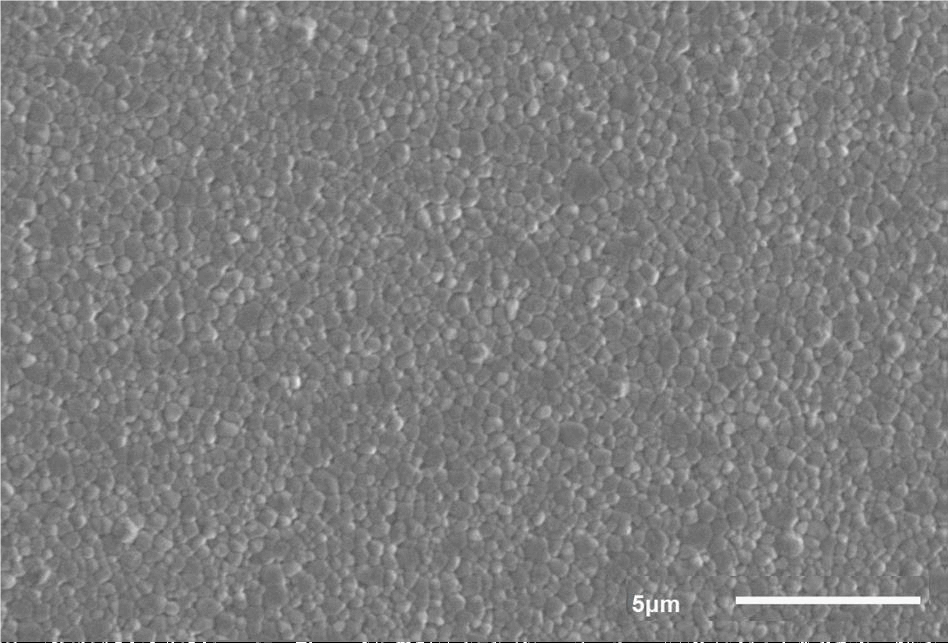

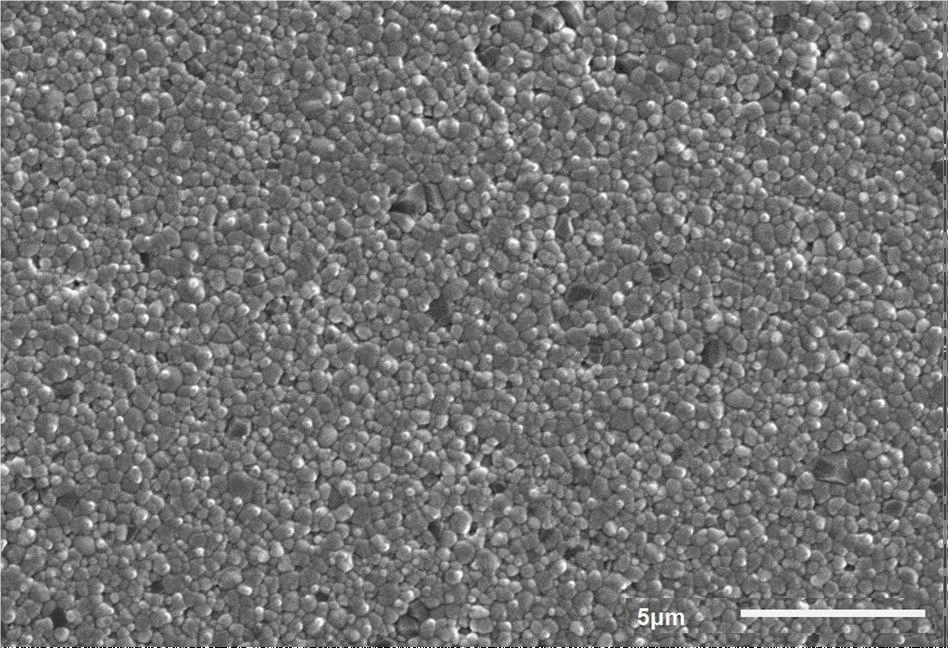

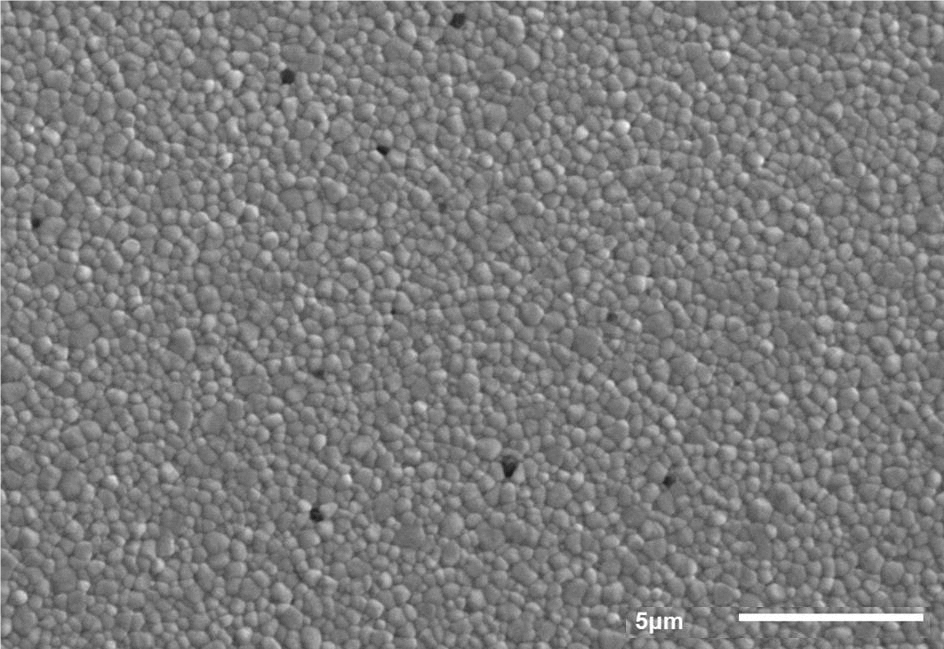

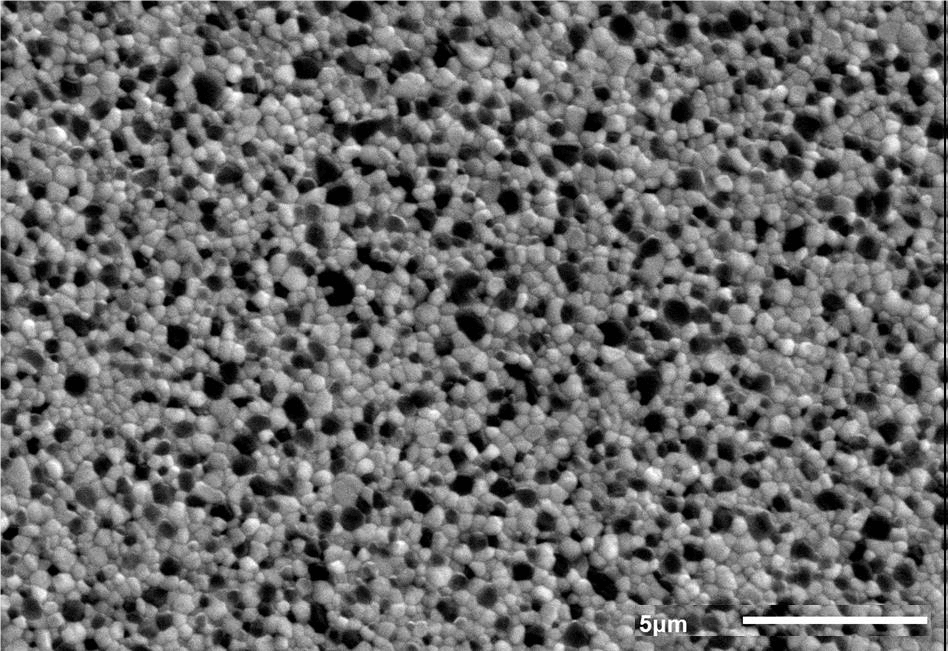

| Grain Size | µm | < 3 | < 1 | < 2 | < 1.5 | < 0.9 | < 0.9 |

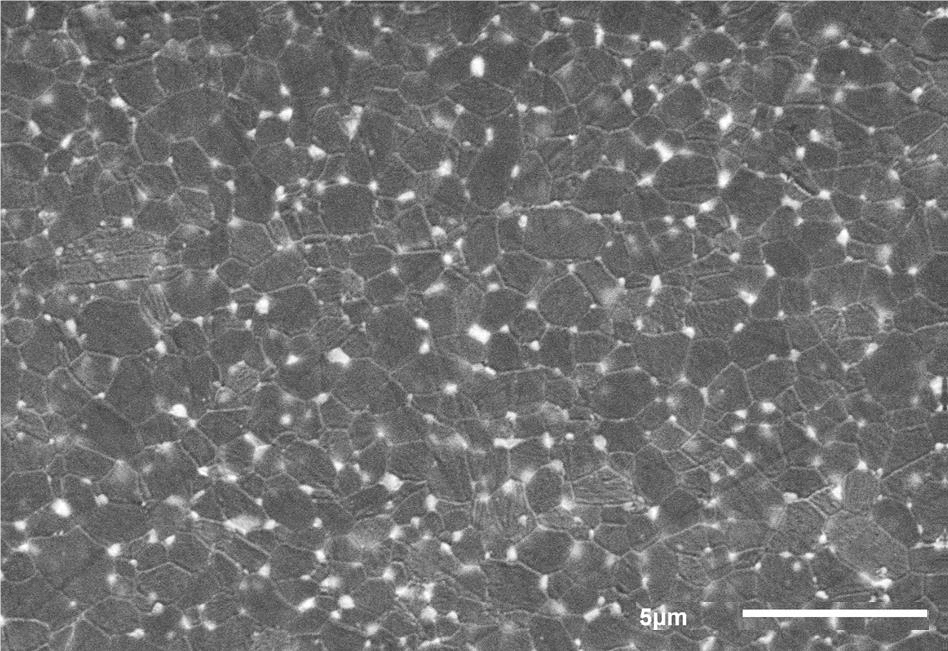

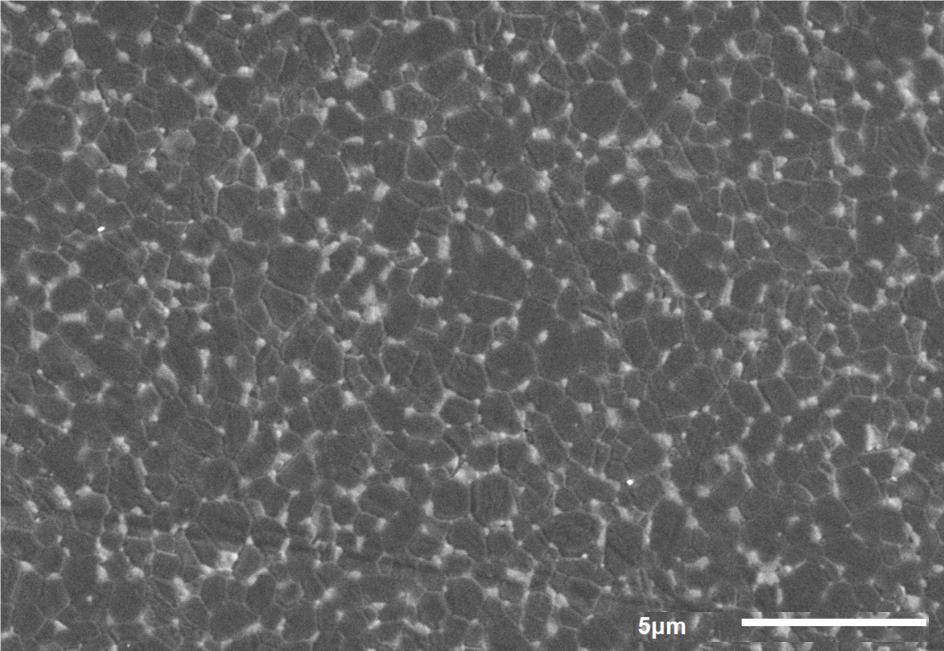

2. Zirconia

| Properties | Units | Zirconia ZrO2-3Y | Zirconia ZrO2-3Y | Zirconia Alumina | Zirconia Alumina |

| SPT Denomination | Z | ZBL | ZF | AZO | |

| Density | g/cm3 | 6.0 | 6.0 | 6.0 | 5.5 |

| Colour | Ivory | Black | White | White | |

| Flexural Strength | MPa | 1'350 | 1'350 | 1'400 | 2'000 |

| Hardness | HV 1 | 1'300 | 1'300 | 1'300 | 1'500 |

| Grain Size | µm | < 0.6 | < 0.6 | < 0.6 | < 0.5 |

Advantages of ceramic materials

Ceramic has a lot of advantages when it comes to production of high precision tools. The main advantage is its hardness. Ceramics are extremely hard, which means they can be used to create very precise shapes. They also have a very low coefficient of thermal expansion. This makes them ideal for use in environments where there are large temperature fluctuations, as the shape of the ceramic will not change significantly with temperature changes.

- Hardness

- Compressive strength

- Chemical inertness

- High melting point

- Corrosion resistance

- Thermal expansion coefficient

- Electrical insulation properties

- Dielectric constant

Ceramic materials are characterized by their high hardness, compressive strength and chemical inertness.

What is technical ceramic?

Technical ceramic is an inorganic, non-metallic material that exhibits superior strength and resistance to extreme temperatures, chemical erosion and electrical degradation. Technical ceramics can be manufactured to precise tolerances and can be designed for a wide range of mechanical, electrical and thermal applications.

There are many types of technical ceramics, each with their own unique set of properties, which make them suitable for specific applications. The most common types of technical ceramics are alumina (aluminum oxide), zirconia (zirconium oxide) and silicon carbide (silicon dioxide).

Technical ceramic materials are typically produced by combining raw powders using a process known as powder metallurgy. The powders are then formed into the desired shape using a variety of methods, including injection molding, isostatic pressing and extrusion. Once the parts have been formed, they are sintered (heated in a controlled atmosphere) to create a strong, dense material.

Ceramic Applications

Ceramic materials are used in a wide variety of applications. Every custom-made, high-precision ceramic part has individual properties and requirements. Please also note the selection criteria for customized production. As the world's leading manufacturer of custom-made, high-precision ceramic parts, our highly qualified employees work together with you, our valued customers, throughout the planning and development process. This is how we optimize the end product and the production chain together in the best possible way.

Some examples of ceramic applications are:

- Ceramic Nozzles

- Ceramic Housings

- Ceramic Valve

- Ceramic insulator

- Ceramic guides

- Ceramic combs

- Ceramic bearings

- Ceramic rotor

Do you have more questions about our ceramic materials?

Don't worry, we are here to assist you. Please send your inquiry by clicking the button below. Thank you very much.