Technology & Experience

Top-quality products require the reliable mastering and continuous development of technology and expertise

SPT stands for maximum precision, quality reliability, and finally for the customer’s success. Get an overview of our capabilities on the following pages.

Ceramics & Precision Mechanics

SPT masters the ceramic injection molding process like no other. We are your ideal partner for the realization of your ceramic project. Our many years of know-how and our enormous vertical range of manufacture are two reasons that allow us to control the entire process and thus deliver the top performance you expect from us.

Ceramics & Precision Mechanics

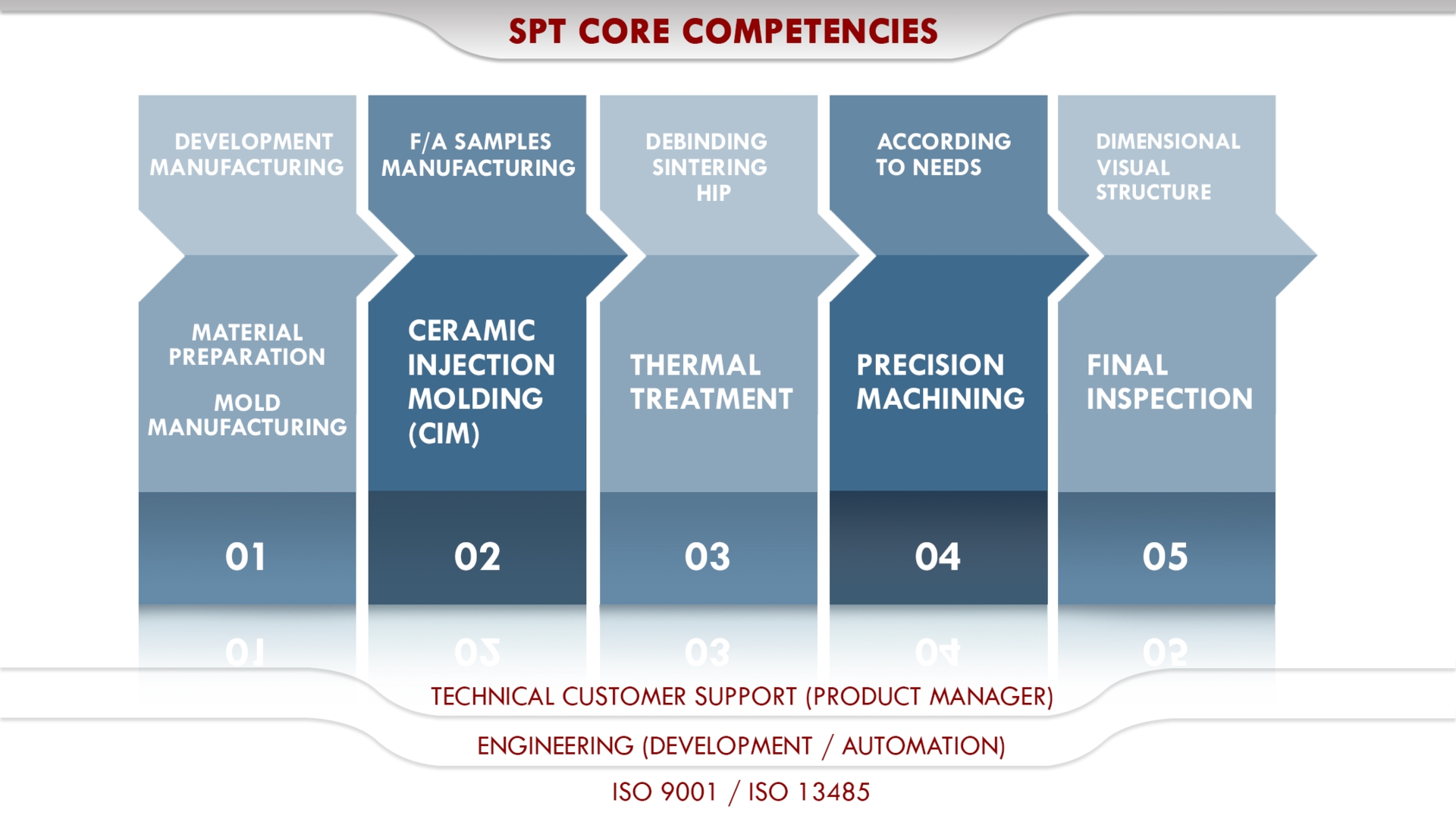

Ceramic Part Making Processes We Control

Ceramic parts are used for many different applications, such as medical devices, dental implants, and even space suits. The materials that are used to create these products vary depending on the application.

SPT is the first contact for customized ceramic components

Through our extensive technology offering, we are your partner for High Performance Ceramics (HPC) products of all kinds

Our customers get added value through the highest level of expertise in the following processes:

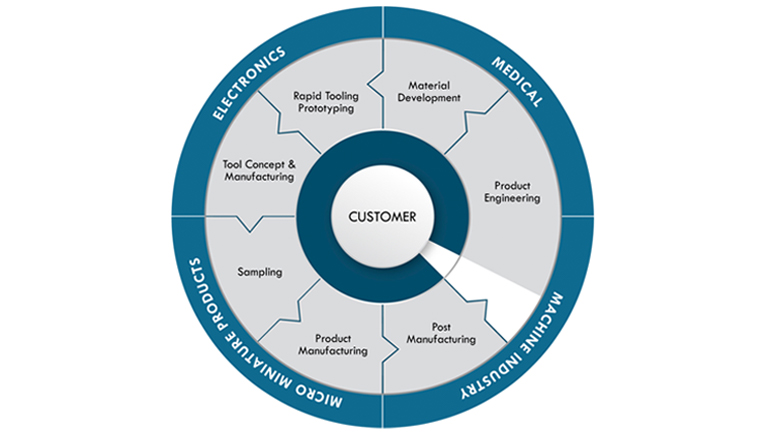

One Stop Solution Provider

SPT in-house processes

- Material preparation

- Toolmaking

- Injection molding

- Thermal processes

- Post-processing

Product Engineering

SPT in-house engineering

- Design support

- Processes

- Industrialization

- Material

- Production

Quality Management

Each and every one of our employees is passionate about producing high-quality products

- Customer satisfaction

- ISO certified 9001 / 13485

- Traceability

- IQ / PQ / OQ

- Process validation

Designing and developing new products.

We design and develop new products for our customers. We also work with them to make sure we understand what they need before we begin production.

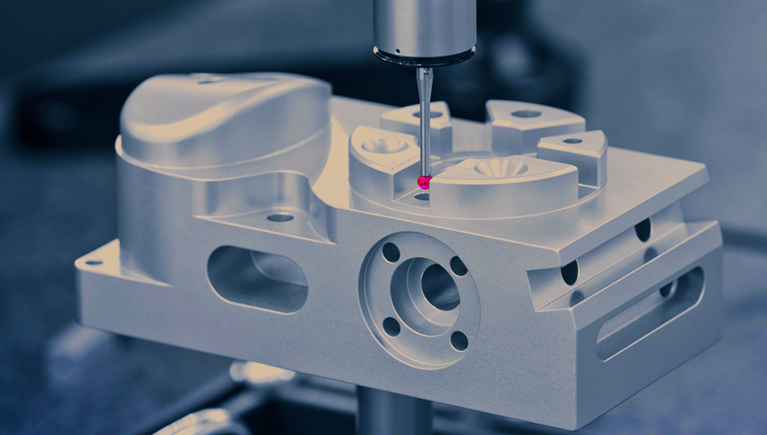

Manufacturing and quality assurance.

We manufacture our own parts using state of the art equipment. We use only the highest quality materials available. We test every product thoroughly before shipping.

Ceramic injection molding CIM

Injection molding is one of the oldest methods used to make plastic products. It is also one of the most versatile processes. This method allows us to produce any shape we need with very little waste.

Ceramic material preparation

We use a variety of materials to prepare our ceramic parts. These materials include clay, sand, glass, metal, and other specialty materials.

Inhouse injection mold manufacturing

We have an in house injection mold manufacturing facility. This allows us to produce high quality molds at competitive prices.