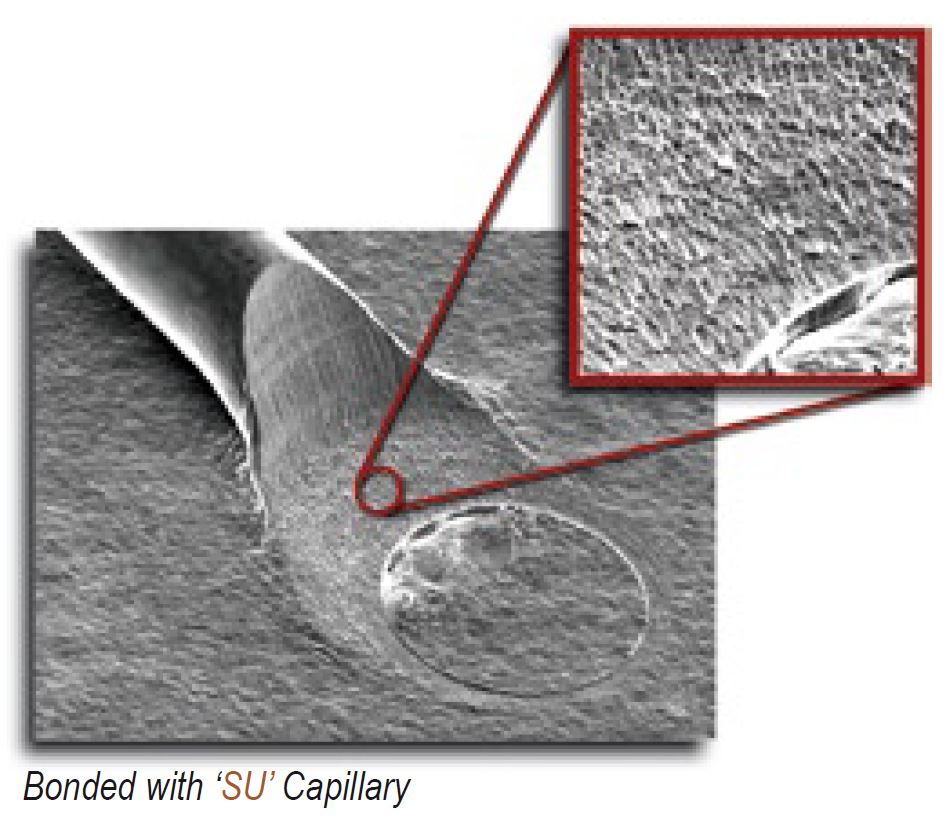

SU Capillary

Special Coupling Finish for Copper Wire Bonding

Copper Wire Bonding

SU Capillaries are the new Standard for Copper - incorporates an excellent durable material with SPT’s proprietary enhanced surface finishing with superior ‘gripping’ features to deliver high reliability stitch bonds for a wide range of copper wire bonding applications from fine wire 15µm to large wire of 100µm wire sizes.

History of Copper Wire Bonding

The history of copper wire bonding packaging interconnect can be traced back to the eighties, spurred then as an alternative to the costly gold. And for decades, SPT has been a leading supplier for numerous customers bonding with large copper wire diameters. Today, copper wire bonding has regained momentum as the semiconductor packaging industry looks for cost reduction alternatives due to rise in gold price, and is commanding more foothold, not only in low pin count discrete packages but fine pitch IC.

Also, copper wire bonding offers other significant advantages over gold – superior performance in terms of electrical and thermal conductivity; better product reliability due to less intermetallic growth causing voids; and higher break load during wire pull testing. However, it also comes with various bonding and process challenges such as oxidation of copper wire at low temperature, ‘short tail’, and ‘fish tail’ which is commonly associated with copper wire bonding interconnect assembly.

SPT the Pionier and Market Leader

A pioneer and a leader in wire bonding tool innovations, SPT has been in the forefront, involved in collaborations with many customers in their development of a new capillary for copper wire bonding application.

SPT has taken its highly successful series, SI (Stitch Integrator) developed for enhanced stitch bondability to the next level, introducing SU – the capillary solution specifically tailored for copper wire bonding.

Bondability

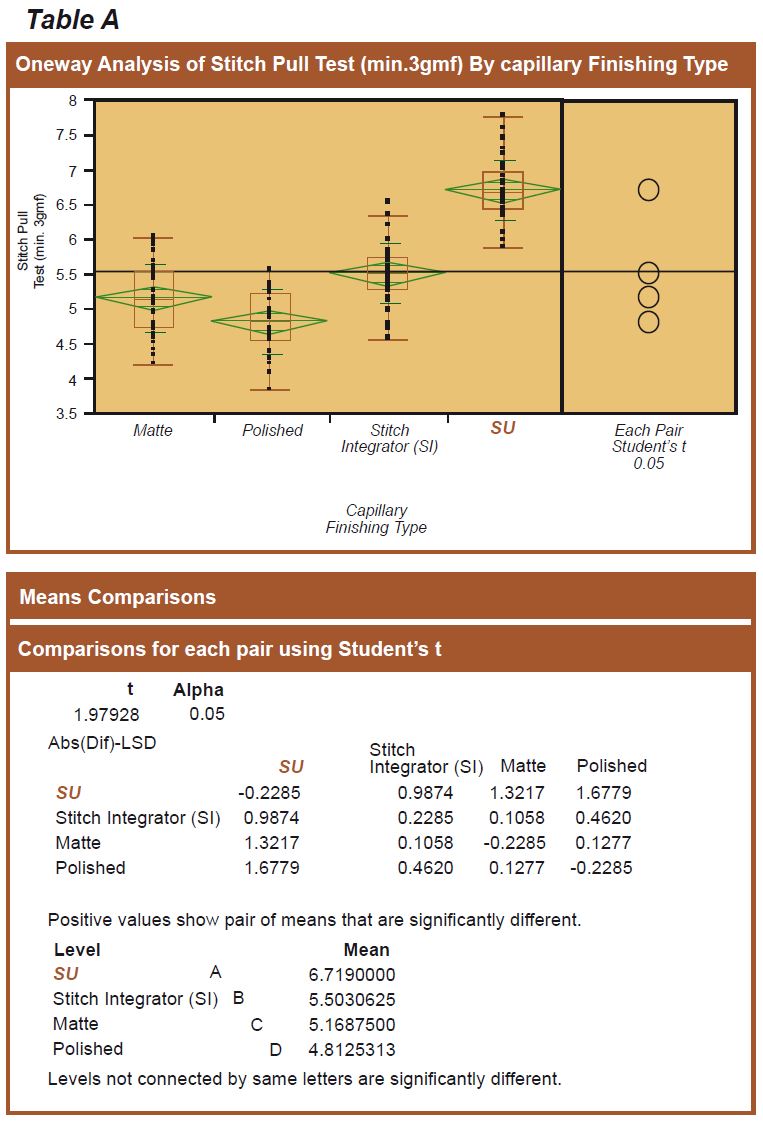

In copper wire bonding process, bond integrity at the interface between the stitch and leaded or laminate surface is measured by using a wire pull tester.

The bonded wire is pulled as close as possible to the stitch, and the pull test strength reading (in gram-force) is taken. Expectedly, the higher pull test strength value is desired, and a remaining stitch failure mode is indicative of a good bond at the interface.

Table A- shows the stitch bond superiority of the SU capillary as the stitch pull test reading is significantly better compared with other capillary finishing types using the same wire bonding parameters, package & device, and copper wire size.

Productivity & Reliability

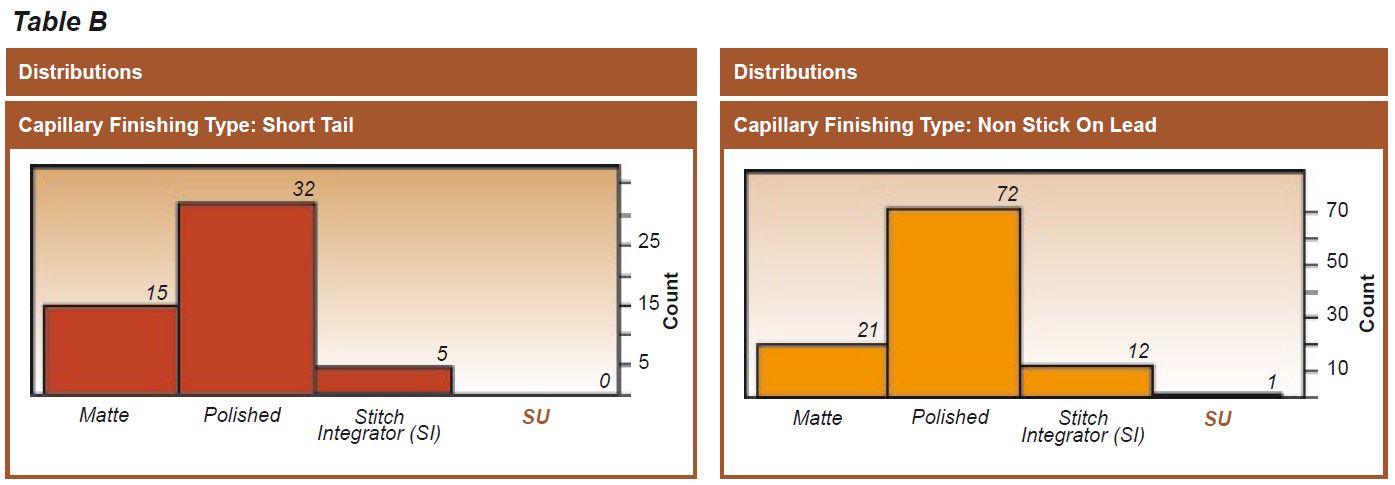

SU capillary has been proven to improve the bondability of the stitch bond while minimizing the occurrence of short tail defects and non-sticking on lead during wire bonding process as shown in Table B. The significant reduction of short tail and non-stick on leads result into increased production output due to lower mean time before assist (MTBA).

Tested by many Customers

SPT’s new SU capillary is the result of extensive research & customer tested solutions to meet today’s copper wire bonding packaging process. SU is the new standard for a robust copper wire bonding process.

Do you have additional questions regarding our SU Type?

No worries, we are here to support you. Please send your request by clicking on the button below. Thank you very much.

Do you need additional Tools?

No worries, we have a huge download repository that includes any Information that you looking for!

BONDABILITY

PRODUCTIVITY & RELIABILITY

SU STYLE VARIATION MATRIX