Medical and Dental Technology

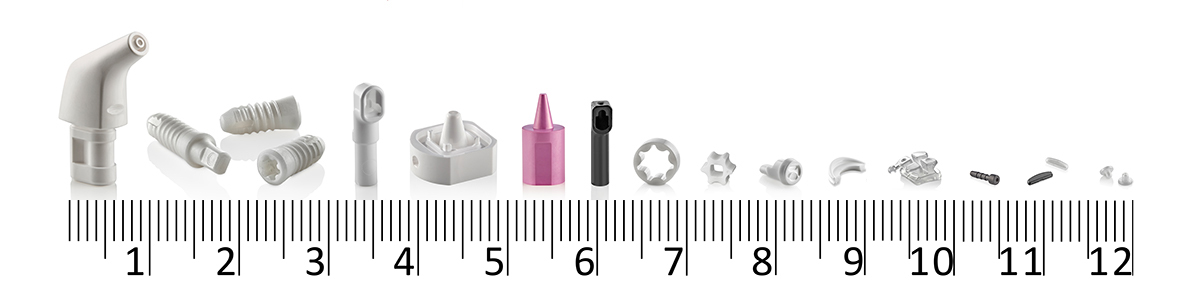

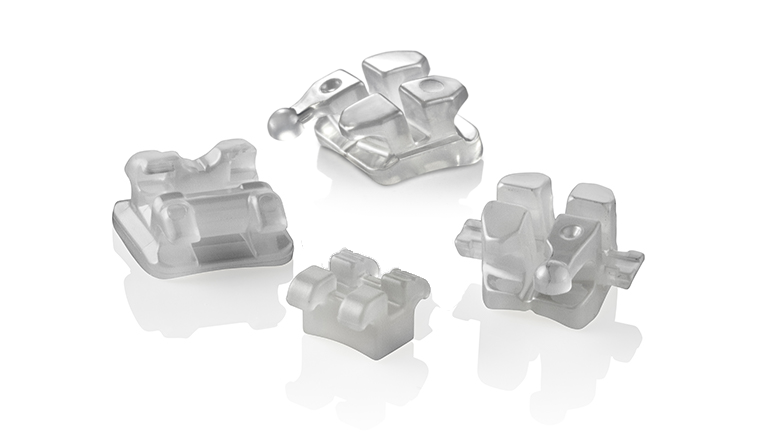

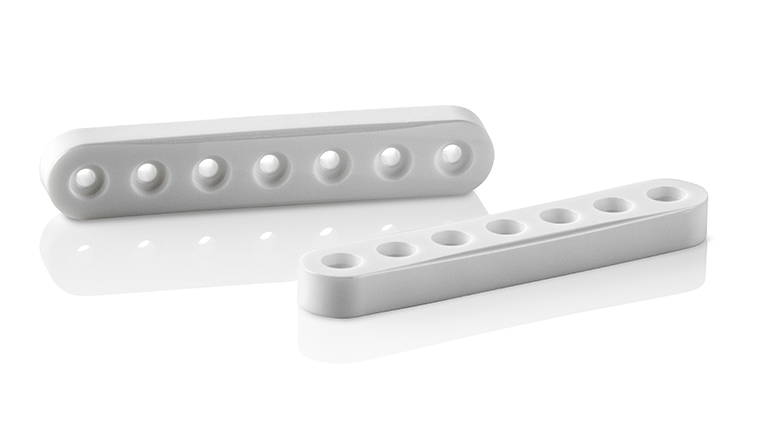

SPT manufactures precision parts in technical ceramics for the dental and medical industry

Ceramic Injection Molding (CIM) enables the economical production of ultra-precise, oxide ceramic microparts for medical and dental purposes. At the same time, the process offers a high degree of design freedom in terms of geometry and material properties, offering more flexibility to your team to design the next innovative treatment options.

| Typical properties of ceramics: | Required product properties: |

|

|