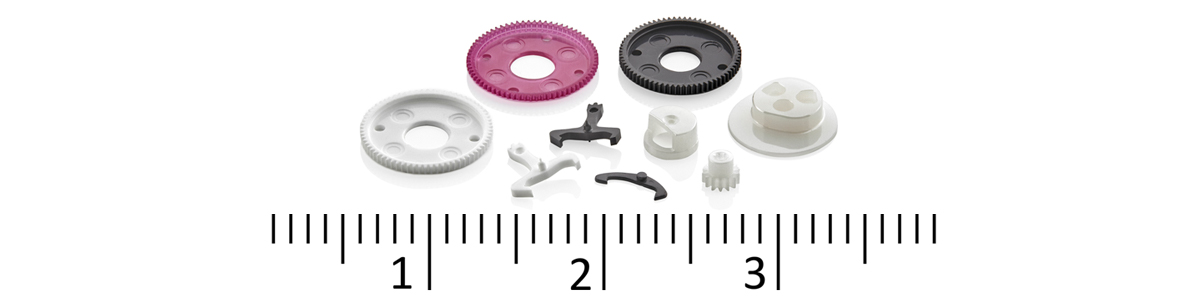

Application examples for different industries

Ceramic Injection Molding enables the economical production of ultra-precise small parts with maximum design freedom in terms of geometry and material properties. In this way, the advantages of the high-performance material are applied in a wide range of industries.

| Typical properties of ceramics: |

Required product properties: |

- More temperature resistant than metal /plastic

- Very high hardness

- Extremely dimensionally stable

- Low thermal expansion

- Very corrosion resistant

- Very wear resistant

- Very good biocompatibility

- Color/transparency can be influenced

- Electrically and thermally insulating

|

- Highest reproducibility in the µ range

- Net-shape without post-processing

- High hardness

- High dimensional stability, even at high temperatures

- High temperature resistance (up to 1,300°C)

- High strength

- Chemically inert

- Highest compressive strength

- Corrosion resistant, even in aggressive media

|