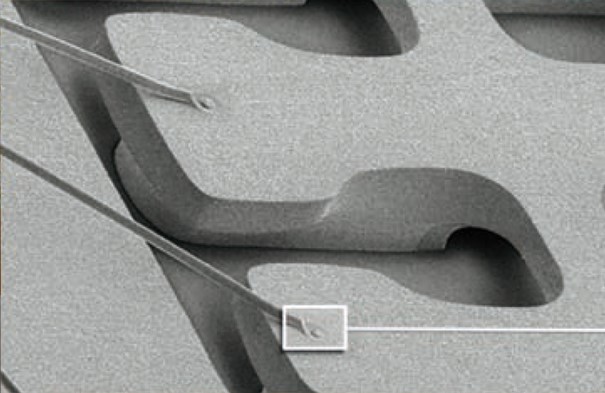

SQ Capillary

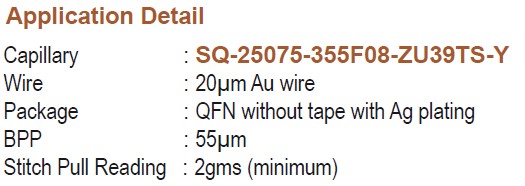

Designed for QFN packages

Higher Productivity & Reliability

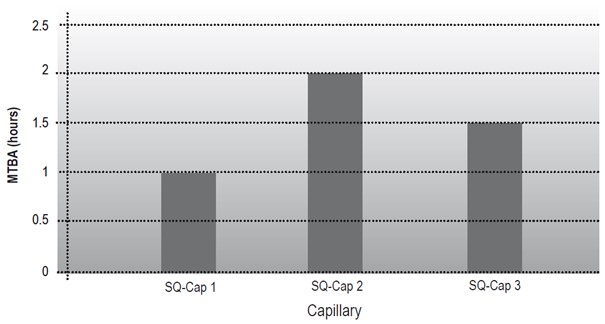

Improved MTBA

With SQ capillary, there will be lesser assist due to short tail or broken stitch which is inherent with bonding QFN package. Experience more machine uptime!

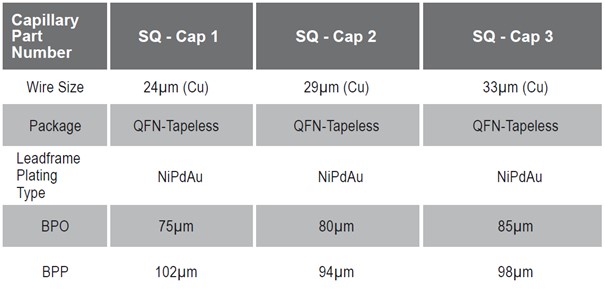

SQ Capillary MTBA Performance using different CU wire diameter

Higher Capillary Touchdown

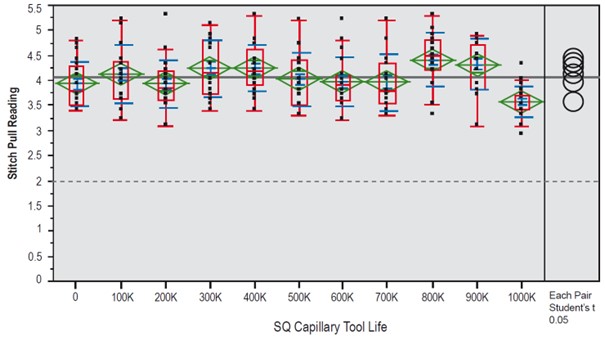

SQ capillary coupled with optimized bonding parameters, has proven to deliver an increase in the capillary tool life as lower bond force (BF) is utilized to bond the QFN package.

Proven Reliability

Whether on gold or copper wire, the SQ capillary is designed to enhance the formation of larger & width stitch bond that will effectively increase the stitch pull reading values & longer size copper remains.

Features

- Improved MTBA- With SQ capillary, there will be lesser assist due to short tail or broken stitch which is inherent with bonding QFN package. Experience more machine uptime!

- Higher Capillary Touchdown -SQ capillary coupled with optimized bonding parameters, has proven to deliver an increase in the capillary tool life as lower bond force (BF) is utilized to bond the QFN package.

- Proven Reliability - Whether on gold or copper wire, the SQ capillary is designed to enhance the formation of larger & width stitch bond that will effectively increase the stitch pull reading values & longer size copper remains

Do you have additional questions regarding our SQ Type?

No worries, we are here to support you. Please send your request by clicking on the button below. Thank you very much.

Do you need additional Tools?

No worries, we have a huge download repository that includes any Information that you looking for!

ONEWAY ANALYSIS OF STITCH PULL READING BY SQ CAPILLARY TOOL LIFE

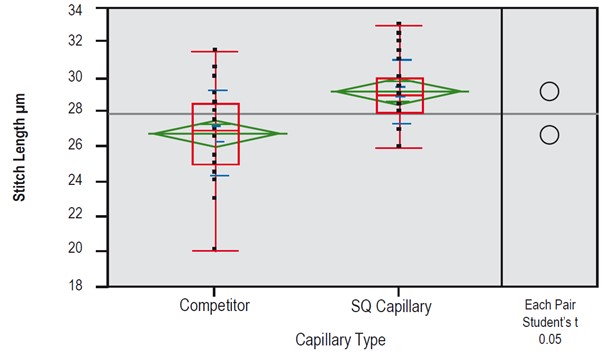

ONEWAY ANALYSIS OF STITCH LENGHT BY CAPILLARY TYPE

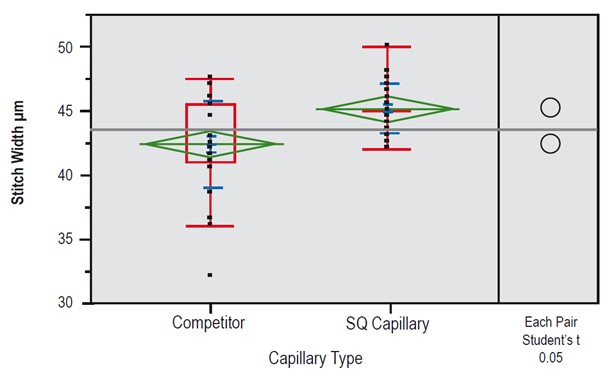

ONEWAY ANALYSIS OF STITCH WIDTH BY CAPILLARY TYPE

COMPETITOR

SQ CAPILLARY