PI Capillary - Wire Loop Capillaries

Ultra Fine Pitch Bonding

P.I. is Capillary ‘Intelligence’ Unprecedented

Designed with Advanced Process Diagnostic Tools

The advancement in bonding technology and the market demand for faster, smaller and better product, again poses new challenges for the wire bonding process. The transition from fine-pitch (FP) to ultra fine-pitch (UFP) volume production, and the emergence of stacked die, multi-tier and low-K bonding has increased the level of difficulties in the wire bonding process with more yield loss due to lifted ball, wire shorts, etc. In compliance with these new bonding requirements, SPT has embarked on an extensive study to develop a new generation and high-performance capillary. Designed with advanced process diagnostic tools, the new capillary design, known as the PI (Programmed Intelligence) capillary has been extensively tested in a variety of wire bonders and packages. In all tests, the PI capillary has demonstrated superior bonding performance with good repeatability and portability using a wide range of bonding platform.

Programmed Intelligence P.I. Capillary - Wire Loop Capillaries

The PI capillary was derived from a series of physical modeling and finite element analysis (FEA) studies to analyze the stress level at the tip and transition profile for different designs, as these are locations where breakage is most likely to occur. An example of the analysis – in this case, for the PI design is as shown below. Among the options considered, the PI design showed the lowest overall stress. This result was validated through destructive test, which showed that the breaking load for the PI design is 7% higher as compared to other design option.

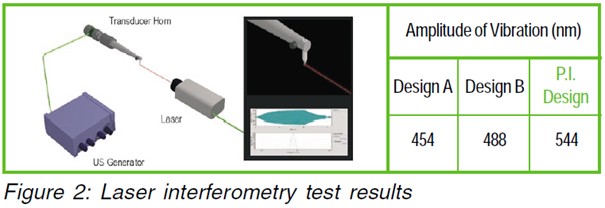

Laser interferometry technique is also used to determine the optimum capillary profile through amplitude of vibration measurement along the overall profile of the capillary. In wire bonding, the vibration characteristics of the capillary is an important factor as its indicates the efficiency of the transfer of the ultrasonic energy from the bonding tool to the bond pad interface. Through the various design optimization, the PI design has shown to be more responsive to the bonding parameters, producing better bond integrity.

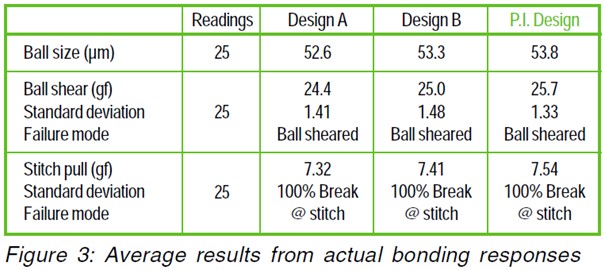

Based on the various simulation and diagnosis, the PI capillary design was conceived. Actual bonding responses were tested using standard QFP and BGA package for a 70um bond pad pitch (BPP). The PI capillary was shown to be more responsive to the bonding parameter producing better results on all the measures (ball size, ball shear and stitch pull). In contrast, other design options would require higher bond force and more ultrasonic power to achieve the same bond integrity. This observation correlated with the result from the laser interferometry test.

Adaptability

Tri-Tier, Quad Tier Bonding for Fine Pitch & Ultra Fine Pitch Application

.jpg)

Reliability

Advanced Stacked-Die Looping for Pyramid& Overhang Stacking

.jpg)

Capability

Standard Forward, Standard Reversed & Special Low Loop

.jpg)

Consistency

Low Loop & Short Wire Capability

Portability

BGA Bonding Application

Repeatability

BGA & QFP Bonding Application

Do you have additional questions regarding our PI Type?

No worries, we are here to support you. Please send your request by clicking on the button below. Thank you very much.

Do you need additional Tools?

No worries, we have a huge download repository that includes any Information that you looking for!

MULTI-TIER BONDING

.jpg)

STACKED-DIE BONDING

.jpg)

ULTRA LOW LOOP BONDING

.jpg)

CHIP SCALE PACKAGE BONDING

.jpg)

ULTRA FINE PITCH BONDING

FINE PITCH BONDING