Precision Processes

Precision Processes in Mold Making, the finishing of Ceramic Parts, and in customized Carbide and Steel parts

Our large vertical range of manufacture enables us to offer you a product "100% made by SPT". Our ability to control the entire manufacturing process and our state-of-the-art machinery are a key success factor for our outstanding results.

High Performance Milling

Traverse path max.: x = 500 mm, y = 240 mm, z = 360 mm

Spindle speed: 42'000 rotations per minute

Special feature: up to 5 axes simultaneously

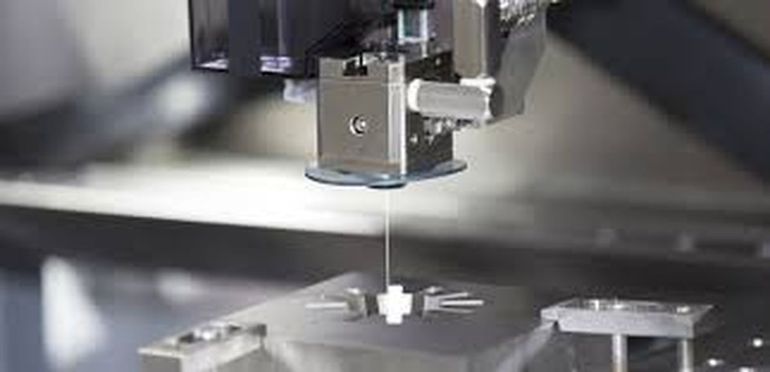

Erode Machining

Types of erode machining: Wire EDM, sink EDM and EDM milling

Precision: +/- 0.002 mm

Smallest hole diameter: 0.05 mm

Smallest wire diameter for wire-cut EDM: 0.5 mm

Smallest hole diameter for die-sinking EDM: 0.1 mm

Smallest possible radius for EDM milling: 0.007 mm

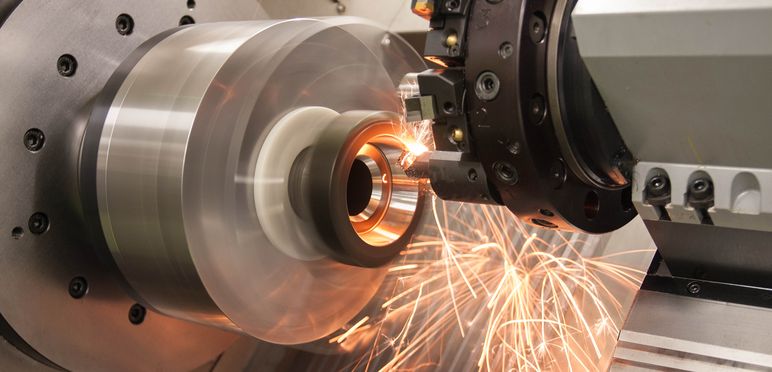

Grinding

Grinding types: cylindrical, flat and internal grinding

Grinding materials: steel, carbide and ceramics

Without grinding heel

Surface roughness: N2

Polishing, Lapping & Honing

Polishing, lapping:

Precision: +/- 0.001 mm

Achievable roughness: N1

Grinding:

Smallest hole diameter: 0.1 mm x max. 30 mm

Precision: +/- 0.001 mm in diameter

Achievable roughness: N2

Hard Turning

Turning of material up to a hardness of 70 hrc

Maximum part diameter: 239 mm

Roughness: N3 (Ra of 0.1 µm)

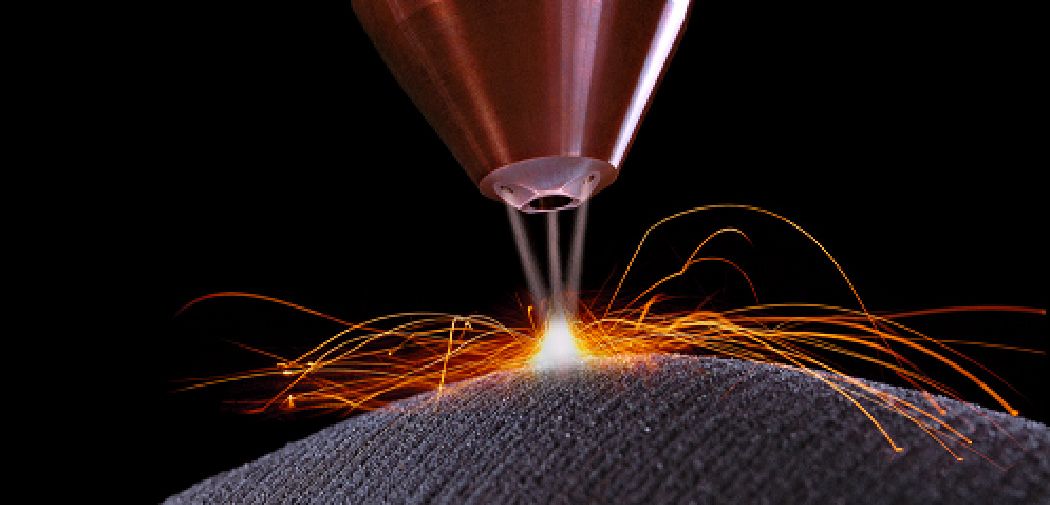

Laser Machining

Processing of various materials such as steel, bronze, and titanium as well as ceramics, sapphire and polymers

Low thermal stress due to femtosecond laser

Tolerances down to 0.1 µm possible

Max. Machining sizes 50 x 50 mm

Roughness: up to max. Ra 0.3 µm possible (N4/N5)